What are E-beam Cables?

E-beam cables are advanced cables manufactured using electron beam processing. This technology involves the use of a focused electron beam to irradiate and cross-link the polymer materials used in the cable's construction. The cross-linking process significantly enhances the cable's mechanical and thermal properties, resulting in cables with exceptional performance and reliability.

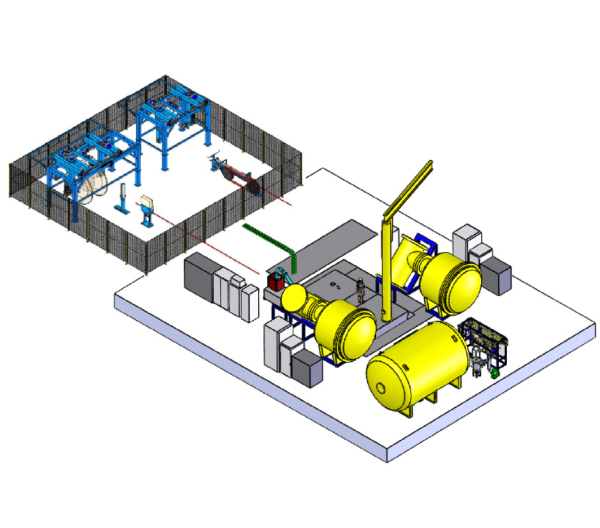

E-beam at Elegar-Kerpen

Our state-of-the-art cables and wires manufacturing facility in Pune and Maharashtra, is equipped with two Electron Beam Accelerators (1.5 MeV x 2) and handles wire sizes ranging from 0.5 sq mm to 300 sq mm. These e-beam accelerators are employed to process specialized products that cater to numerous industries.

Applications of E-beam Cables

E-beam cables find diverse applications in critical industries:

-

OEM Industry

Ideal for OEM Industry and Customized solutions for enhanced strength. Their resilience to harsh environments suits critical application. -

Solar & Wind Power

Preferred choice for renewable energy installations, enduring outdoor exposure in solar panels and wind turbines with superior resistance and extended service life. -

Transportation

Vital for railways, automobiles, and aviation, providing seamless communication and data transmission, enduring vibration, mechanical stress, and temperature variations.

Advantages of E-beam Cables:

The use of E-beam technology in cable manufacturing offers several advantages, making them a preferred choice in critical applications:

-

Enhanced Mechanical Strength:

The cross-linking process improves the mechanical strength and resistance of E-beam cables, reducing the risk of damage during installation and operation. -

Extended Temperature Range:

E-beam cables can operate effectively over a wide temperature range, making them suitable for both extreme hot and cold environments. -

Chemical and Abrasion Resistance:

These cables exhibit excellent resistance to chemicals, abrasion, and other environmental stresses, ensuring longevity and reliability in challenging conditions. -

Reduced Downtime:

With their high reliability and durability, E-beam cables minimize maintenance requirements, leading to reduced downtime and enhanced productivity. -

Higher Electrical Performance:

The electron beam cross-linking process results in cables with improved electrical properties, reducing signal loss and enhancing overall electrical performance. -

Environmental Benefits:

E-beam cables are manufactured with an eco-friendly approach, as the cross-linking process eliminates the need for certain chemical additives, making them more environmentally friendly. The cable is also RoHS and REACH compliant.